Demolition of quay walls can be a long and costly process, making their repair or improvement a more cost-effective solution. [Company] has a wide portfolio of techniques combined with extensive experience to design a bespoke solution adapted to any situation.

Usos frecuentes

Extend the lifetime of existing wharves and limit the need of new investments

Mitigate effects that can reduce the lifespan of different structures

Allow modernisation of wharves and vessel accommodation

Draught increase to accommodate larger vessels

Repair of corroded structures or poorly executed sheet piles retaining walls

Settlement mitigation

Proceso

[Company] can design and deploy solutions to meet specific soil conditions and client requirements.

Example solutions include:

- Execution of Soilcrete columns behind a corroded combi wall wharf to ensure its water-tightness and restore structural strength

- Execution of compaction grouting below the bottom of a quay wall in settlement

- Execution of minijet anchors to restore the lateral support of a quay wall

- Detection of declutched sheet piles and execution of Soilcrete columns to stop any material leakage through the wall and later settlements of the platform of the wharf

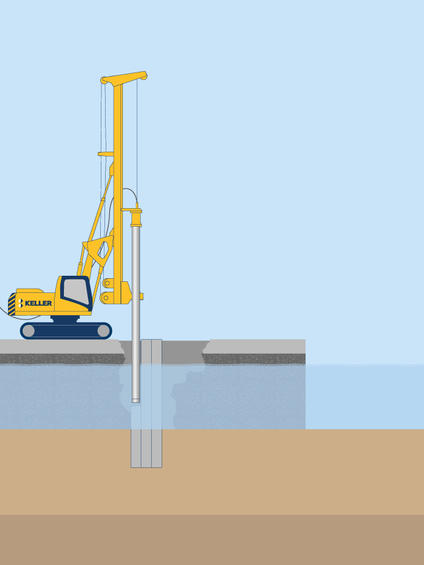

- Execution of secant pile retaining wall at the bottom of a wharf to allow deeper dredging and increase the draught

- Execution of Soilcrete columns below a caisson wharf to allow deeper dredging and increase the draught

Ventajas

[Company’s] broad product portfolio means our engineers have more options when it comes to an effective and efficient designs for our clients

The experience to design solutions specific to specific conditions and requirements

Ability to call on a global network of experts to support. Combined with our local ground knowledge, this enables us to create the optimum solutions